about

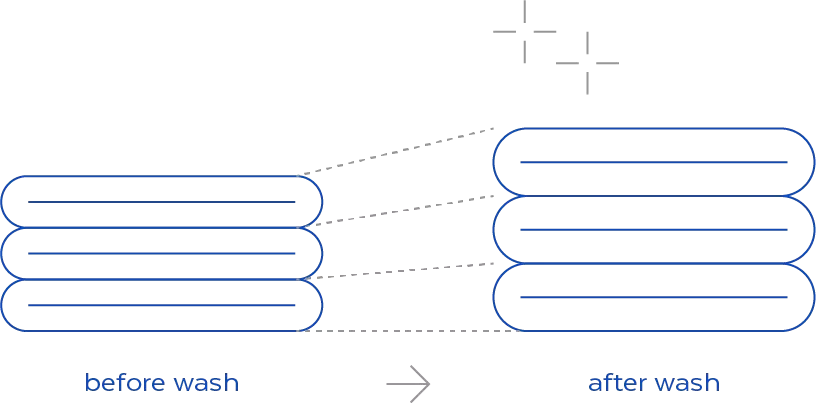

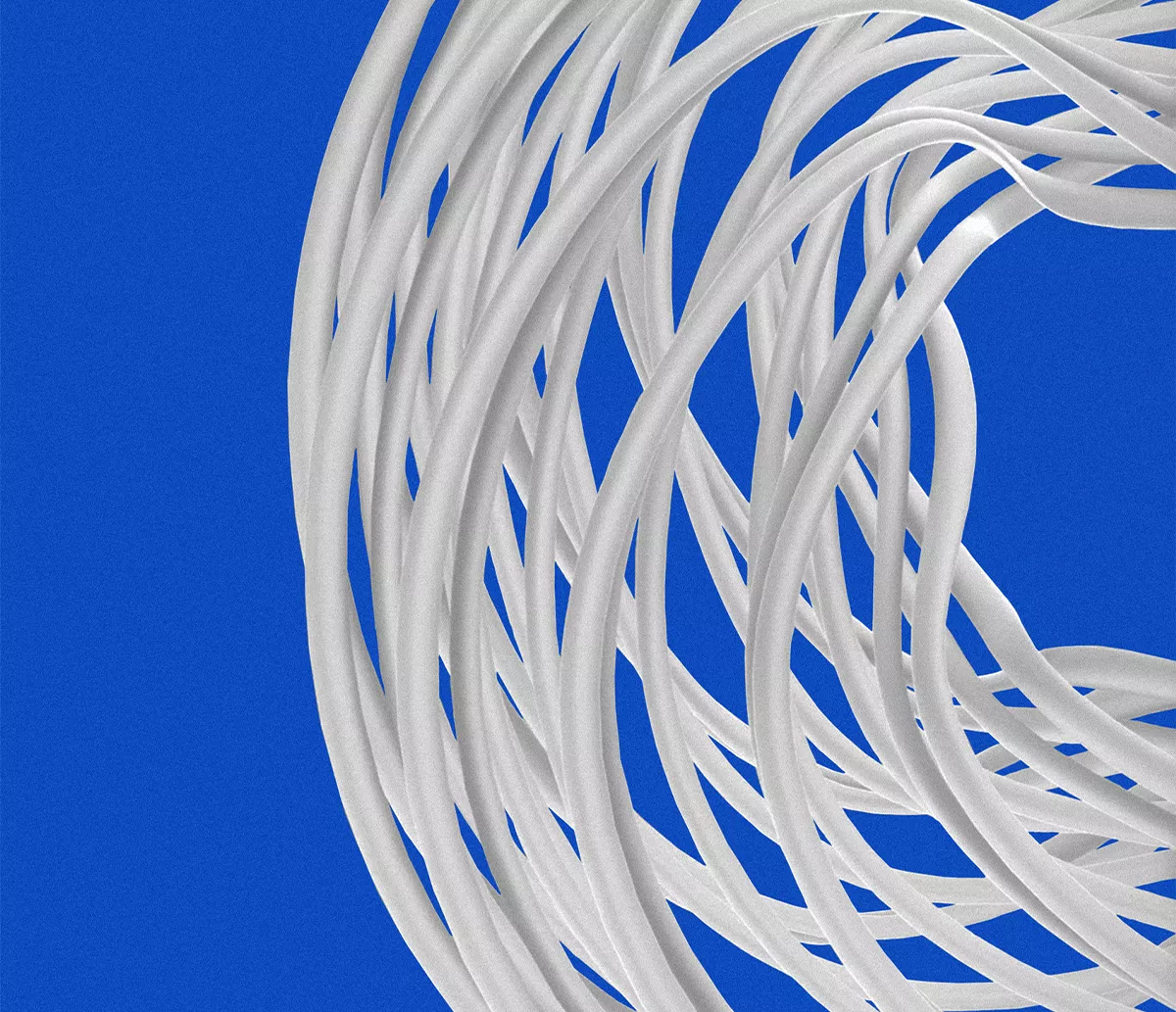

To twist yarns, or yarns that have been twisted are called “nenshi(twisted yarn)” in Japanese. "super zero®︎", which received its world patent, is the fusion of the traditional nenshi method and cutting-edge technology.

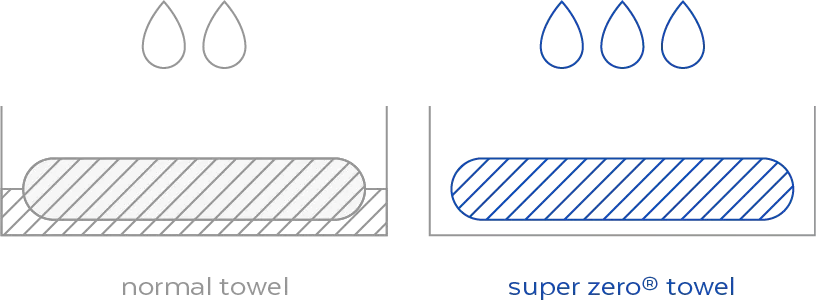

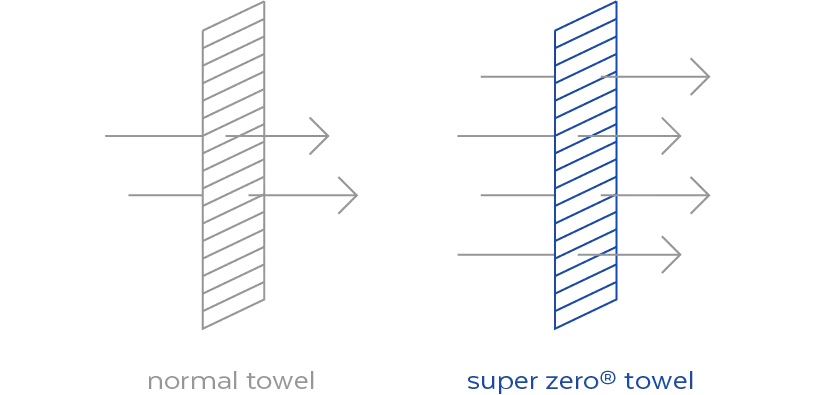

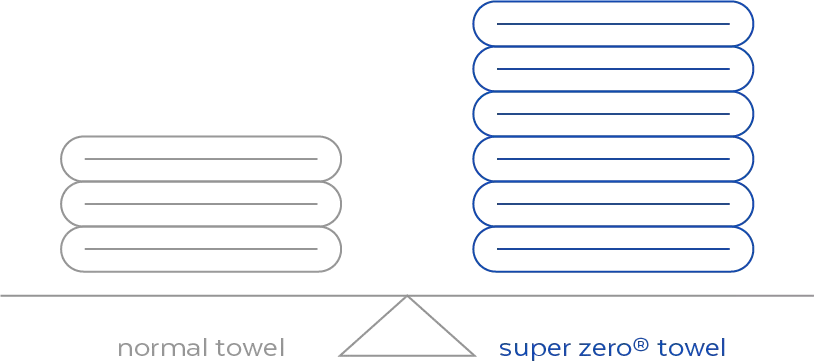

It is light and gentle on the skin and easily absorbent. This unique technology can be applied to cotton and wool, silk, linen, and other yarns.

"super zero®︎" is a revolutionary new material, developed by using a vacuum steam press that we invented. We believe that this yarn has unlimited potential to take yarn-twisting technology to a new dimension.