T.01

thread

technology

- 01

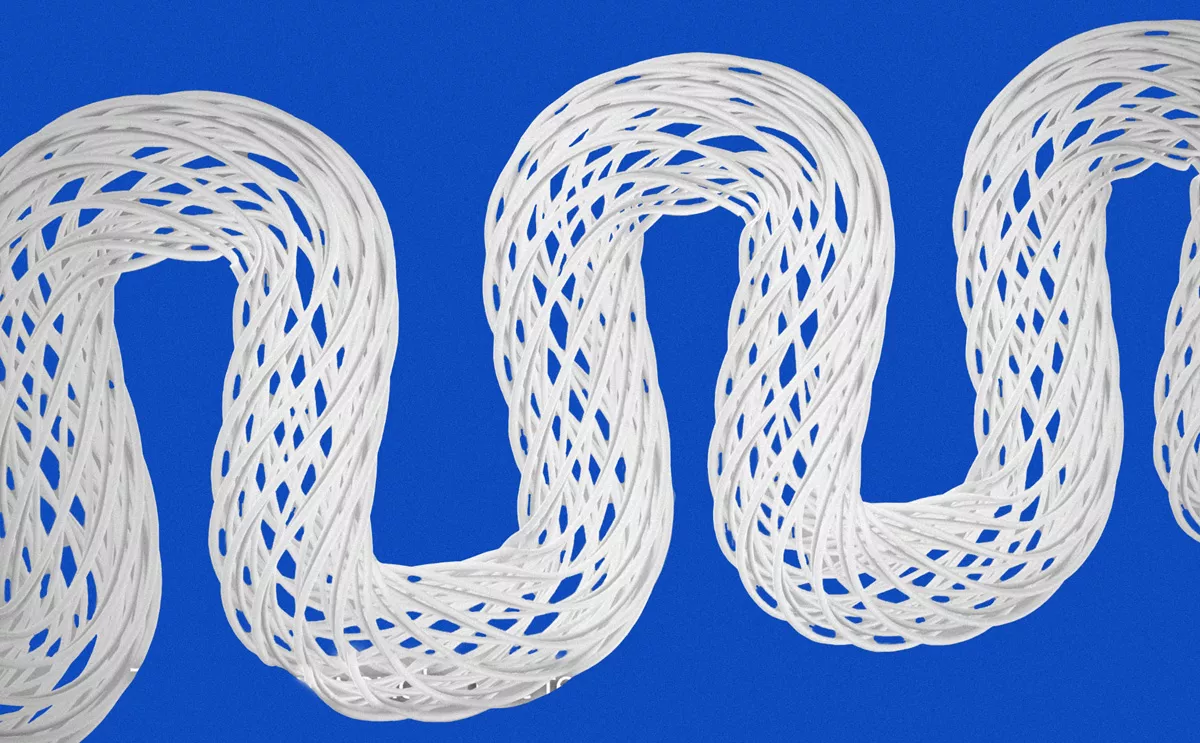

- twist

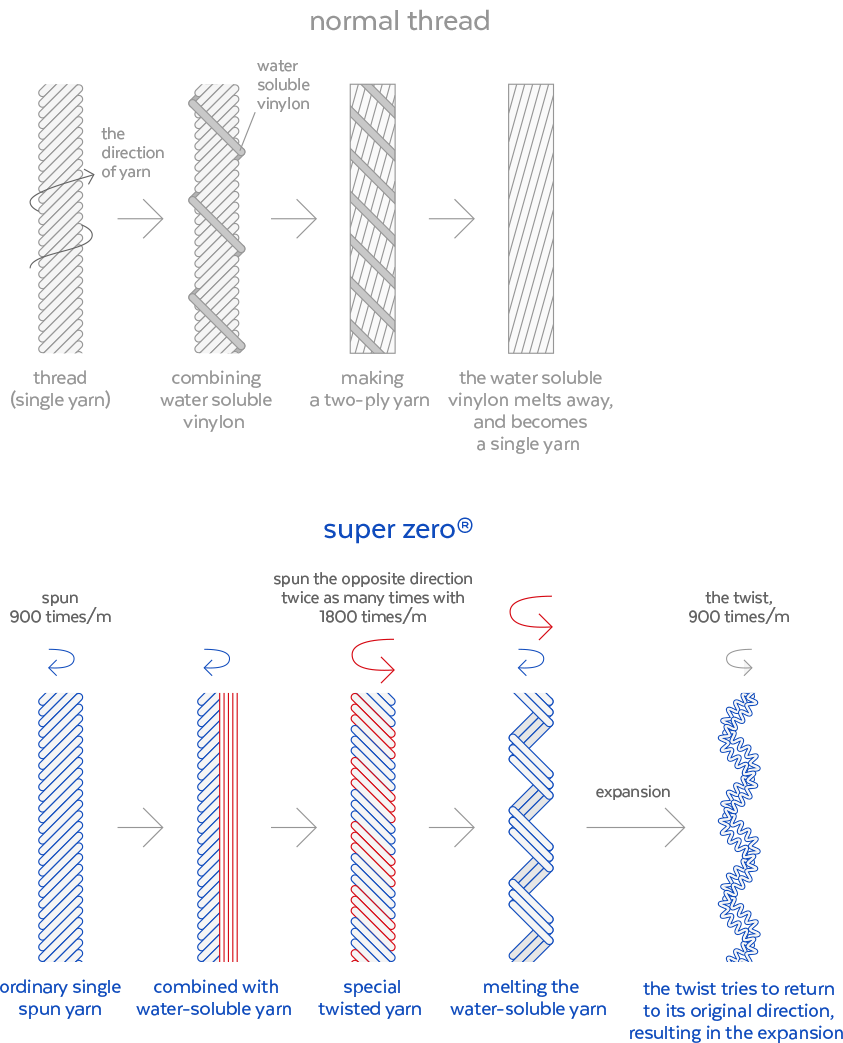

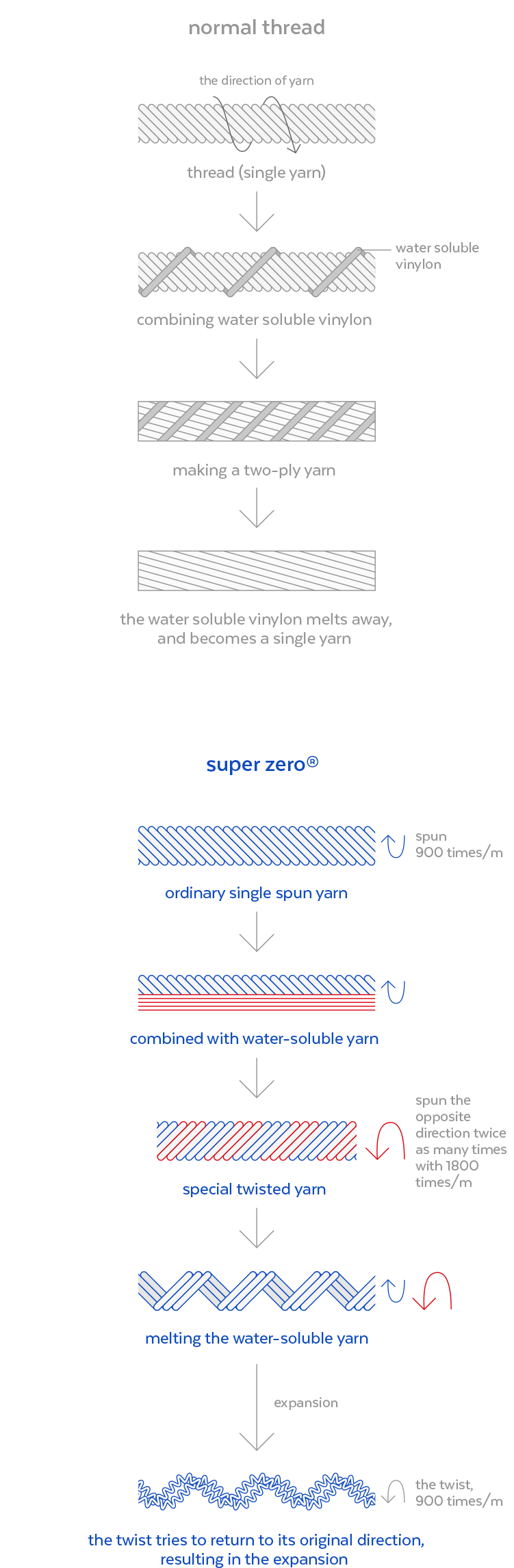

- Combining left twisted yarns with water-soluble yarns, which is then twisted again in the opposite direction.

- 02

- dissolve

- Undergo hydrothermal treatment to melt the water-soluble yarns.

- 03

- expand

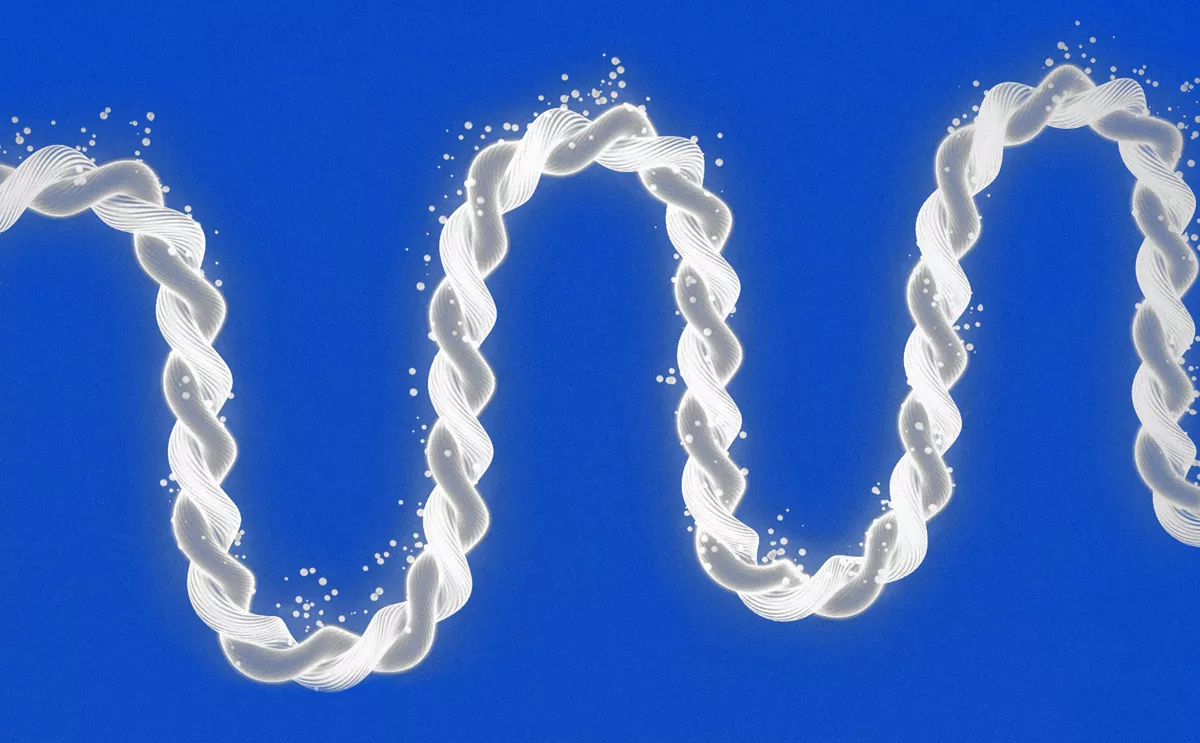

- Due to the water-soluble yarns melting, the cotton tries to return to its original direction, which results in the thread expanding in size.

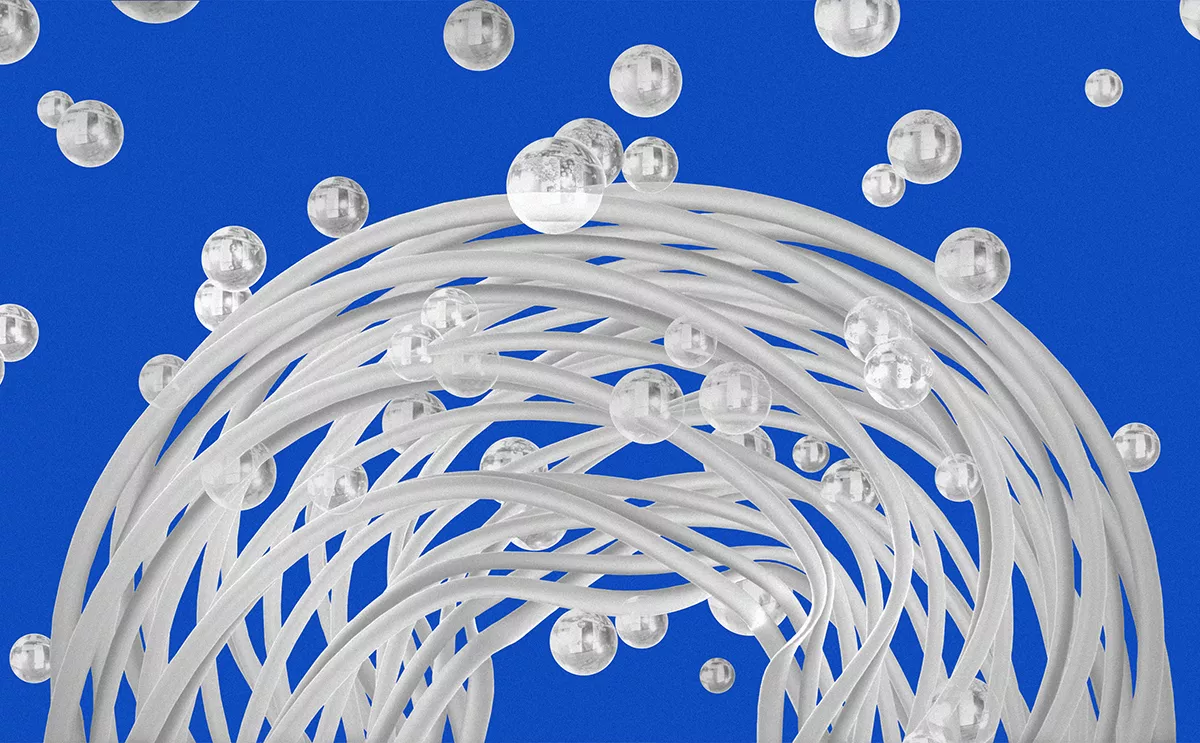

- 04

- aerate

- This allows air to enter the gaps between the threads, creating a yarn composition with high absorbency that retains its fluffy texture.